Approximately ten sets of hands and hearts enrich every Denimsmith pair of jeans…

This is an increasingly rare but encouraging fact to learn from a Melbourne label who is taking ‘locally made’ to a whole new level.

Denimsmith could not be further from the fast-fashion norm we now see everyday. They are a business passionately dedicated to preserving the history and hard work of the local community, and launched in 2015 as a collaborative vision of veteran Australian designers and makers who are committed to the ethical production of denim clothing.

Focused on quality and slow fashion, they are a family owned business and proudly accredited by Ethical Clothing Australia.

“Each Denimsmith piece is created from the finest denim and comes directly from our teams skilled hands and hearts” says Denimsmith Director and Master Jean Maker, Vinh. “When I shop with my wife we are surprised to see the amount of poor quality garments available. However, I have to believe there is a market for good quality, well-fitted Australian made garments, otherwise I would close my factory doors tomorrow”

Due to the fact that the last denim mill closed its doors in Australia over ten years ago, Denimsmith now ensures that all of their materials are ethically produced overseas, with the bulk if their denim being sourced from Japan, yet still every item in their collection is handmade in their East Brunswick Studio + Factory + Store, right here in Melbourne.

Their garments are not only stylish and timeless (further promoting the responsible consumption of fashion), but Denimsmith also offer a ‘repair and re-wear’ service so you can enjoy your pieces for years to come. After wearing your Denimsmith jeans or jackets to death, their makers will provide your first repair free of charge. With any further future repairs charged at a very reasonable $30 (amazing!)

I was lucky to attend Denimsmith’s HQ for the “Denimsmith x Vege Threads Signature Collection” launch and it was a surprising, but welcome delight to see Australian fashion still being produced locally.

“It is very tough to make locally made garments a viable business” Vinh explains, “But I continue to believe we need to keep jobs in Australia. Our Factory is a family business and I want to look after my family both now and in the future”

Denimsmith ticks many boxes, with its ethical practices & sourcing, excellent hand crafted fit and overall quality. They are a company that is supporting local designers and makers and in turn should be supported by us.

Please read on below for my interview with the Denimsmith team and a video of their Melbourne factory.

Can you tell us a little about Denimsmith and how the brand came to be?

Denimsmith is a unique business, because we’re not just a brand – we’re also a collaboration of veteran Australian designers and makers, a family, studio, factory and store. Our makers own our brand and we value the ethics and transparency that this provides.

Our parent company Vince Clothing Pty Ltd manufactured denim collections for local brands for over 20 years, in response to the fast fashion movement many Vince Clothing customers started to move their production overseas. In order to keep local employment Vince Clothing Pty Ltd believed there was still a market for good quality, well-fitted Australian made garments. So in collaboration with veteran Australian designers and makers who are committed to the ethical production of high quality denim clothing, they formed Denimsmith in 2015.

What sets Denimsmith apart from other denim wear labels?

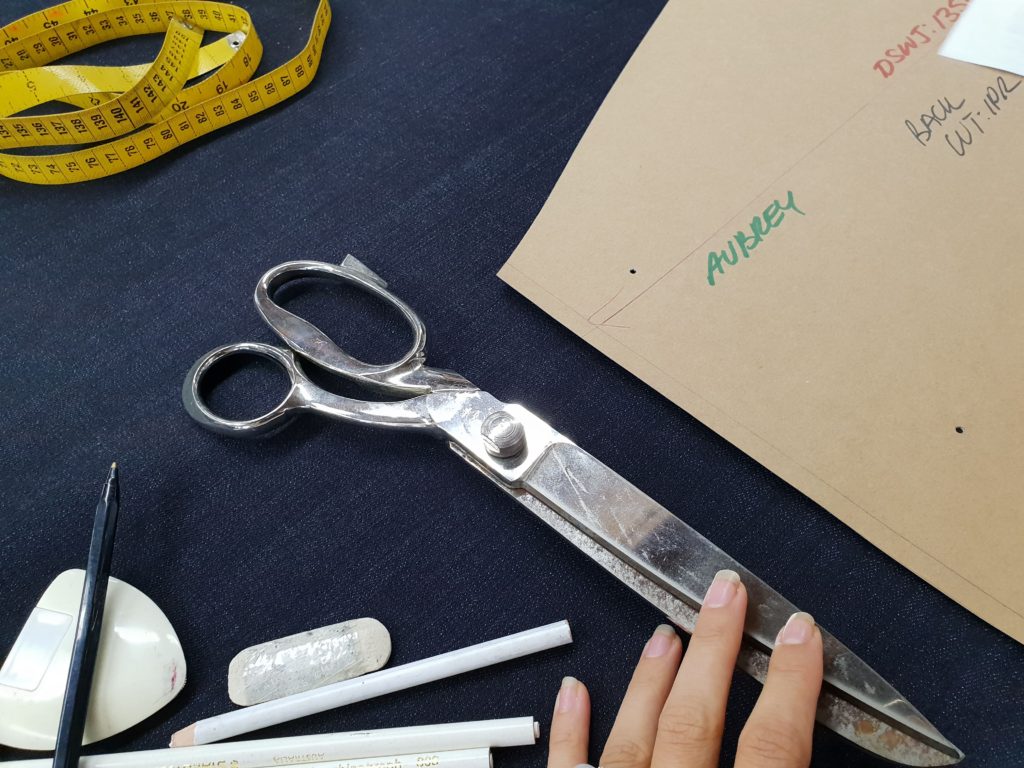

Aside from the high quality material we use to create every piece, at Denimsmith our veteran Australian designers and makers have over two decades of denim expertise, so despite being in a time that embraces technology, we still do everything by hand. For example, many fashion brands use computers for the design and pattern making processes and machines for the production, such as cutting, sewing, buttons, rivets and labels. Now although you may think that we’re not taking advantage of all the benefits technology provides, we’ve purposely chosen to continue to hand make our items, not only because we love what we do, but because you just can’t beat the quality.

It’s also important to note that all our makers have the skills and capabilities to create a whole garment, so rather than specialising in one aspect, like pockets, they can create any item from start to finish.

How would you best describe Denimsmith’s design aesthetic?

Authentic and timeless are two words that best describe Denimsmith’s design aesthetic, which is supported by the superior fabric, exceptional quality and fit that each item provides.

Can you tell us a little bit about your teams creative/production process?

Approximately ten sets of hands and hearts enrich every Denimsmith item which is born in our Studio, by our Creative Director who sketches our designs and selects the materials. Once finalised our pattern makers bring the designs to life, ensuring each item has the perfect fit. The patterns then get passed onto our Master Jean Maker, Vinh, who does the chalking and cutting, in preparation for the sewing, pockets, buttons, rivets, labels and washing. When we’re creating new items for our two seasonal fashion collections, it’s a very collaborative process to ensure every element is perfect before it then goes into production and onto our retail and online stores.

What’s a typical day at the studio/office/factory for the Denimsmith team?

It really depends on what day you visit our Studio + Factory + Store in Brunswick East, as each day is slightly different. However what is consistent is that each day our makers are in the factory creating quality items with their hands and hearts, while also serving any customers that visit the store. As a family business, our makers all eat lunch together at midday, which I think is a really special ritual.

What are 3 styles of Jeans that every one should own?

It really comes down to your personal style – skinny, straight, wide or flare. Once you’ve determined your style preferences, we’d recommend you own three Denimsmith jeans in a mix of washes and styles if you have more than one preference. As this mix will allow you to seamlessly transition through the seasons and as part of our ‘repair and re-wear’ service, once you’ve worn them to death we can breathe new life into your Denimsmith jeans. So for example, if your style is a straight leg then for women we’d recommend our MABEL, LUCIA and PAYTON Jeans and for Males we’d recommend our JAX Jean in a Light and Mid Indigo, as well as a Dark Indigo or Washed Black/Nero.

Tell us about some of the people who inspire Denimsmith and why?

Our makers and the creative community in which we’re based in continually influence the brand. The passion and dedication of our makers, combined with their exceptional skills and the machines in which they use make our Studio + Factory + Store in Brunswick East a really inspiring place to work. Likewise, the buzz of local artist industries and independent brands in Brunswick East creates an incredible vibe to be amongst – we love meeting new artists and creators, while also continuing to connect with veteran ones.

What are the top 3 resources that you team turn to for inspiration?

It all comes down to Melbourne’s diverse, incredibly unique and vibrant lifestyle, of which the top three sources of inspiration would be:

Street fashion

Local musicians / gigs

Local art exhibitions

What is next for Denimsmith?

Our customers are always at the heart of our business. We are continually focused on making improvements to our local industry and providing our customers with the best possible experience when they visit our Studio + Factory + Store to view our jean making process.